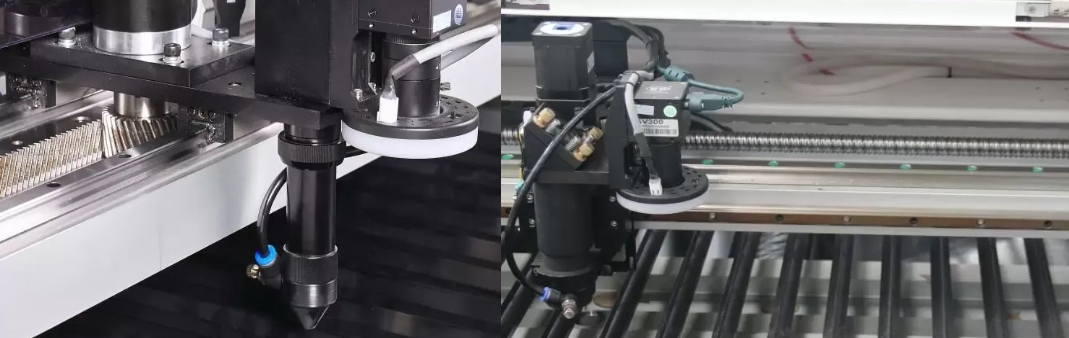

Gear and rack

Gear racks are divided into straight teeth and helical teeth. Compared with straight teeth, helical teeth have a larger meshing area, and the transmission between the gear and rack will be smoother.

Working principle: Gears and racks are parts that can mesh with each other. Racks are divided into straight teeth and helical teeth. Racks and pinions change rotation into movement, or movement into rotation. Can change the speed of movement and change the direction of movement.

Advantages of rack:

♦ The rack can be infinitely extended, suitable for long-distance conveying movements;

♦ The load-bearing capacity of the rack is stronger than that of the ball screw, and it can work under high load and heavy load;

♦ The transmission between gears and racks will be smoother.

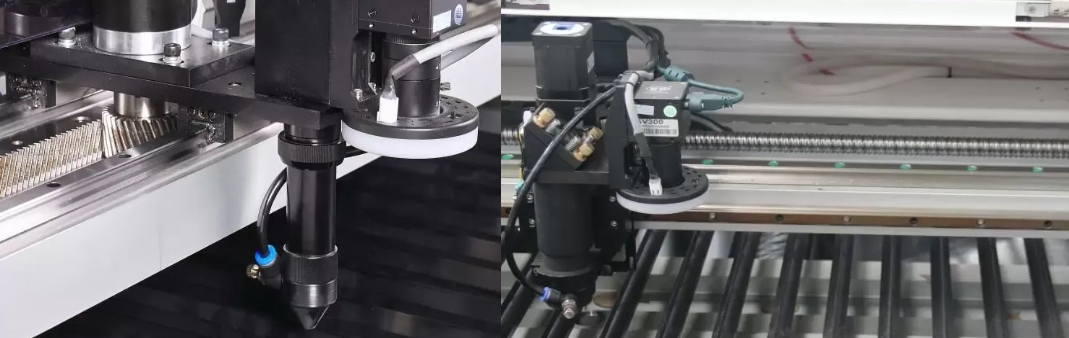

Ball screw

The main function of the ball screw is to convert rotational motion into linear motion, or to convert torque into axial repeated force. Due to its small frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

Working principle: The ball screw is composed of screw, nut, steel ball, preloading piece, reverser and dust protector. Its function is to convert rotational motion into linear motion or linear motion into rotational motion.

Advantages of ball screws:

♦ High precision: High-precision ball screws have small errors and high precision, allowing for more precise motion control.

♦ High rigidity: High rigidity can avoid loosening and shaking during movement.

♦ High reliability: longer life and lower maintenance costs. Equipment failures and downtime losses caused by environmental factors can be avoided.

Summarize

The transmission distance of the rack and pinion can be longer and the structure is simple, but the accuracy is limited; the ball screw has high accuracy and low friction, but the manufacturing cost is high and the structure is complex.