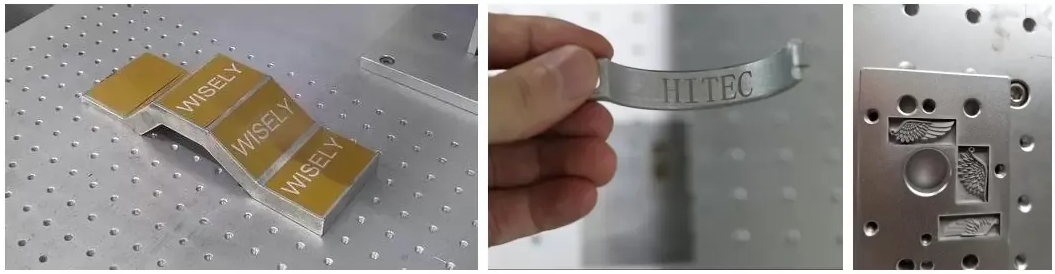

2D Fiber Laser Marking Machine: ONLY engrave on a flat surface, such as logo making, serial numbers, technical specifications, and other designs on metals (copper, iron, steel, stainless steel, titanium, aluminum, gold, silver, Brass Marking alloys, etc.) and ABS, etc. However, the working area of the fiber laser engraving machine is mostly 100*100mm, there have optional lens can bigger the engraving area: such as 70*70mm, 110*110mm, 150*150mm, 200*200mm 300*300mm Most of them are also equipped with low-power laser sources, such as 20w 30W 50W 60w 80W and so on.

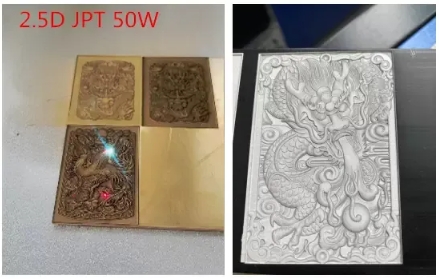

2.5D Fiber Laser Marking Machine: From the technical part, we called it 2.5D because the laser head is still with a 2D laser head, but 2.5D with a motorized lifting pillar. And Galvo head can be controlled by software. the software can control the laser head movement when the machine working, so it can achieve 3D engraving. it means 3D laser, Z axis mirror inside laser head to move back and forth; 2.5D, Z axis stands for the third mirror to move automatically

2.5D laser engraving machine can finish all 2D laser work and can make 3D laser engraving on a flat plate. BUT it CANNOT make 3D engraving on curved parts.

The lifting pillar of the 2.5D laser machine must be motorized type. Because the laser head needs to re-adjust the focus during engraving,

Summary: can finish all 2D laser work and can make 3D laser engraving on a flat plate. 2.5D CANNOT make 3D engraving on curved parts.

3D Fiber Laser Marking Machine: 3D means dynamic focusing. Compared with ordinary 2D fiber laser machines, 3D laser marking machines use different Laser heads. Ordinary 2D fiber Laser Machines use 2D galvo scanning heads that have only two mirrors, while 3D fiber Laser machines use 3D Dynamic focus scanning head scanning heads that have three mirrors. The third mirror can be moved back and forth. This is the key technology of a 3D laser marking machine.

1) Curved laser engraving

The 3D fiber laser Machine working area is usually below 300*300mm. We can use it to engrave curved and Ball surfaces. Unlike rotary engraving, 3D curved surface engraving has very high accuracy and automatically adjusts the focal length.

2) Embossing laser engraving

Embossing laser engraving is as popular as Curved laser engraving. We can use it to make many handicrafts, gifts, molds Retro coins and stamps, etc. But the purpose is Mainly for Material to do deep engraving

Although the 2D laser machine can do deep engraving, all the depths are the same, on the same plane. 3D laser engraving can reach different depths, behaving like a three-dimensional pattern, with a three-dimensional effect.

3) Large working area engraving

As we know the maximum working area size of the 2D laser marking machine is 300*300mm. But many customers require a larger working size. Using a 3D laser marking machine, usually, its working size can reach 600*600mm. As for the larger size, it will require a customized scan head.

Jinan Sequoaytec Co.Ltd. supplies 2D Fiber Laser Marking Machines, 2.5D Fiber Laser Marking Machines, 3D Fiber Laser Marking Machine, MOPA Fiber Laser Marking Machine, CO2 Laser Marking Machine, etc.